Poor Quality Assurance did just that, in 1963. Lack of Quality Assurance procedures and non-adherence to standards can be just as disastrous in your environment!

Poor Quality Assurance did just that, in 1963. Lack of Quality Assurance procedures and non-adherence to standards can be just as disastrous in your environment!

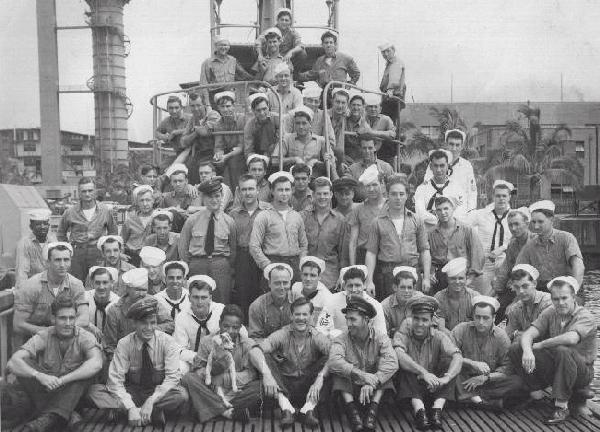

Let me take a step back. I would like to share a little of my Navy Career with you so you can understand why I am so “Gung Ho” about Quality Assurance.

I entered the Navy on October 28, 1963 and the USS THRESHER (SSN-593) was lost on April 10, 1963, so you can imagine how personal this is for me.

I received extensive technical and leadership training while working on Nuclear Submarines in 1965. My Career started as a pipefitter welder and advanced to a Quality Assurance Visual and Nondestructive Testing Examiner. (that’s a big title to go with the responsibility!)

By 1968, one of my areas of expertise was performing Ultrasonic Silver Braze Inspections. In my position, my training was to assure non-negotiable compliance to all repairs and overhauls on Nuclear Submarines. Try telling the Admiral his ship can’t leave because of a brazing! Well, Sir, if the brazing fails, then (insert disaster here). Sometimes I got my own brazing for the announcements! But, In QA, you always have to stand your ground or face the consequences.

That was, essentially, my responsibility. To this day in the Nuclear Submarine Navy, an Officer, Engineer or even a Rear Admiral cannot reverse or negotiate a rejection made by an Inspector.

The USS THRESHER (SSN 593) is the foundation for my Quality Assurance Integrity. My goal is the never see another “Thresher” incident at one of my clients. Not on my watch! I’ve worked with tens of thousands of workers on all types of problems.

The common denominator of these problems are always complacency and non-compliance.

You can read accident and incident reports from many catastrophes and see this pattern. This was especially true with the Thresher, as well as in the loss of our two space shuttles, Columbia and Challenger.

|

|

With the Thresher, here is some more history from a statement by Rear Admiral Paul E. Sullivan, U.S. Navy Deputy Commander for Ship Design, Integration and Engineering Naval Sea Systems Command:

Before the House Science Committee on the SUBSAFE Program 29 October 2003:

USS THRESHER (SSN-593) was lost at sea with all persons aboard – 112 naval personnel and 17 civilians. The USS THRESHER was the leading edge fast, quiet and deep diving nuclear submarine.

THRESHER had about 3000 silver-brazed piping joints exposed to full submergence pressure. During her last shipyard maintenance period 145 of these joints were inspected on a not-to-delay vessel basis using a new technique called Ultrasonic Testing. Fourteen (14%) percent of the joints tested showed sub-standard joint integrity. Extrapolating these test results to the entire population of 3000 silver-brazed joints indicates that possibly more than 400 joints on THRESHER could have been sub-standard. One or more of these joints is believed to have failed, resulting in flooding in the engine room.

- The crew was unable to access vital equipment to stop the flooding.

- Saltwater spray on electrical components caused short circuits, reactor shutdown, and loss of propulsion power.

- The main ballast tank blow system failed to operate properly at test depth.

- The Thresher was unable to overcome the increasing weight of water rushing into the engine room

Loss of THRESHER was the genesis of the SUBSAFE Program.

Yes, ONE or more poorly inspected brazing failed and caused this terrible disaster!

If you’re interested in the Admiral’s full statement, here it is:

Learn about Quality Assurance from us and avoid your own “Thresher”!

In other nuclear sub news….

Never take snapshots in a nuclear sub and send to friends!